The following points should be noted in the use of carbide punching needle:

Brief introduction: Hard alloy is a mixture of metal carbide powder and cobalt, commonly used metal carbide is tungsten carbide, titanium carbide, niobium carbide and vanadium carbide, they can make hard alloy with high hardness and high wear resistance characteristics, hard alloy is a kind of efficient tool material, it is the high melting point, high hardness of metal carbide powder mixed with binder, By pressing the workpiece into various shapes by powder metallurgy, the hard alloy can be guaranteed to have certain strength and toughness.

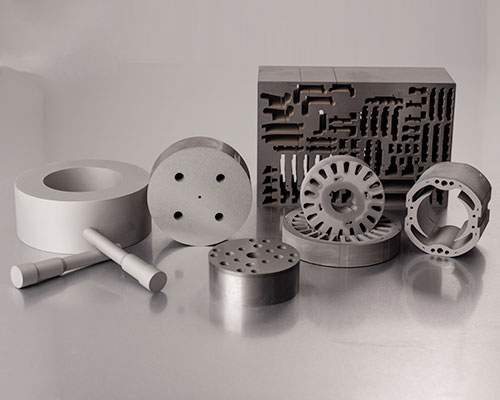

Carbide punching needle, also known as tungsten steel punching needle, tungsten steel punching needle punch, by hard alloy rod fine grinding, has the characteristics of high precision, high hardness and good bending strength, suitable for hardware mechanical and electrical processing industry, generally installed on the stamping die for punching, so that the material separation or plastic deformation, so as to obtain the required parts. Hard alloy punch needle has the characteristics of long service life, corrosion resistance and no rust because of high hardness, and is widely used in industrial machinery manufacturing.

Hard alloy punching needle because the whole is made of tungsten steel material, and because hard alloy has high hardness and a certain brittleness, so in the use, installation, handling impulse should pay attention to the following matters:

1. The cemented carbide punch needle should be installed in place and fixed firmly.

2, the size of the pressing pressure of the carbide punch needle should be appropriate, and can not be adjusted too large, in order to avoid the damage of the punch due to excessive pressure.

3, stamping stroke should be set reasonable, stamping stroke is short not only easy to damage the material, waste increase, more direct damage to the punch.

4, whether packaging, installation or disassembly, use process shall not throw, throw, knock tungsten steel punch, so as to avoid the carbide punch due to external impact of collapse, damage.