The prospect of cemented carbide is immeasurable

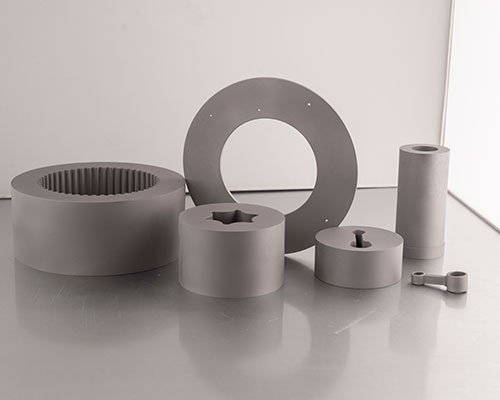

Hard alloy has high hardness, strength, wear resistance and corrosion resistance, known as "industrial teeth", used in the manufacture of cutting tools, tools, drilling tools and wear-resistant parts, widely used in military, aerospace, mechanical processing, metallurgy, oil drilling, mining tools, electronic communications, construction and other fields, with the development of downstream industry, hard alloy market demand is increasing. In addition, the development of high-tech weapons and equipment manufacturing, advanced science and technology and the rapid development of nuclear energy will greatly improve the demand for carbide products with high technology content and high quality and stability. According to the Forward analysis, from the 2013-2017 China hard alloy industry market Outlook and investment strategy planning analysis report, it is estimated that the output of China's hard alloy will reach 30,000 tons in 2015, and the total industrial output value will reach about 23 billion yuan. Tungsten steel alloy manufacturers

South Korea YesTool company launched the "KRUZ" hard alloy machine clip hole processing tool, the use of hard grains of 0.2+0.5+0.8μm mixed type of high cobalt (13%) ultrafine grain size matrix, so that the strength and hardness of the tool matrix material have been greatly improved, With the geometric structure and clamping method of the machine clip blade close to the strength of the whole drill bit, the original drill point design and the high performance titanium nitride (TiN) and titanium aluminum nitride (TiAlN) nano physical coating (PVD), not only suitable for processing soft to hard workpiece, even for the very difficult to process the special material workpiece, can reflect the excellent cutting performance.

Sweden's SandvikCoromant (SandvikCoromant) new steel turning grade GC4225, GC4235, using the superfine grain gradient hard alloy matrix, with titanium nitride carbide medium temperature chemical coating (MT-CVD) and fine crystal columnar a-Al2O3 chemical coating, On the surface, the post-treatment process of eliminating surface stress was adopted, that is, the tensile stress surface (TiN) of the CVD coating on the front tool surface was removed by shot peening, and the tensile stress of the exposed Al2O3 on the surface was reduced by 40% and that of the inner coating by 20%, which significantly improved the anti-micro breakage performance and anti-spalling ability of the blade. In addition to improving the integrity and reliability of the blade, it also improves the finish of the coating surface and reduces the bond between the blade and the chip. The GC4225 can cover 80% of applications from rough to finish. Compared with ordinary P25 blades, the cutting tool life can be increased by 60%, and the production efficiency can be increased by 33%. Zhuzhou Diamond Cutting Tool Co., Ltd. introduced two years ago the YBD series of black gold steel brand for iron processing, the newly launched second generation of black gold steel brand for steel processing, YBC152 and YBC252, also adopt the gradient hard alloy matrix material with cobalt-rich surface. With thick layer of fibrous TiCN and fine grain Al2O3 CVD coating, has strong plastic deformation resistance and cutting edge strength, especially suitable for high-speed steel processing. Under the same cutting conditions, the cutting speed can be increased by more than 25%. At the same cutting speed, tool life can be increased by more than 30%. New brands of cobalt-rich gradient cemented carbide matrix materials were also introduced at this exhibition: Kennametal's universal material grade KU30T, Valenite's processed stainless steel grade VP5535, Israel's ISCAR's improved Al2O3MT-CVD composite coating "a-TEC" series suitable for high-speed processing (e.g. IC9150, IC9250, IC9350), etc.

Adding a small amount of elements to hard alloy can strengthen the hard phase and bonding phase of the material, purify the grain boundary and improve the bending strength and impact toughness of the material significantly. Japan Sumitomo Electric Carbide Co., Ltd. launched ACE series coating brand (AC700G, AC2000, AC3000), the use of zirconium (Zr) carbide matrix material, so that the new brand matrix material red hard greatly improved. The HG series coatings (HG8010, HG8025) launched by Hitachi Tool Technology Co., LTD., adopt the so-called "triple zirconium effect" CVD coating technology. The "first zirconium effect" is to add zirconium (Zr) element to the carbide substrate material to improve the high-temperature deformation resistance of the substrate. The "second zirconium effect" is to replace the usual MT-TiCN coating with a fine crystalline cylindrical zirconium (Zr) coating, thus improving the oxidation resistance of the coating. The "third Zirconium effect" is to coat the surface with a white zirconium (Zr) coating to improve the lubrication, heat resistance and spalling resistance of the tool surface. This new coated blade has good heat resistance and is especially suitable for high efficiency processing. Compared with traditional blades, it can increase the processing efficiency by 150% and reduce the processing cost by 20-30%.

Superfine grain carbide has been used more and more widely. In addition to the new brands of the above companies, the new brands of Kennametal, KC5525 and KC5510, also adopt the high cobalt carbide matrix with refined grain, which has the super refined grain with 10% cobalt content and the TiAlNPVD coating with high aluminum content. The cutting tool has high cutting edge toughness in intermittent cutting, but also has a strong thermal deformation resistance. ISCAR's "AL-TEC" line of coatings for monolithic carbide end milling cutters (e.g. IC900, IC903, IC908, IC910, etc.), the same use of ultrafine grain carbide matrix, with high aluminum content TiAlN(PVD) coating, so that when milling hardened steel with hardness up to 60 ~ 62HRC, compared with the original IC903, the tool life is increased by 150%. Valenite's VP1595, which is used for high-speed turning of cast iron, is also coated with TiCN/Al2O3/TiC coating of 18μm thickness using MT-CVD on the matrix of ultrafine grain carbide, and the back tool surface is coated with a layer of gray TiC, in order to observe the wear condition of the cutting edge and blade transposition. The processing efficiency of this brand is 50% higher than that of other K05 ~ K10 brands when roughing nodular cast iron.

As can be seen from the above new brands, with the improvement and enhancement of matrix material properties, tool coating technology has made more rapid development. Medium temperature chemical coating, cylindrical A-al2o3 chemical coating, high performance physical coating, new atomic coating, nano-structure coating, yellow aluminum oxide chemical coating, white zirconium coating, high aluminum content TiAlN coating, TiSiN coating, CrSiN coating, AlCrSiN coating, TiBON coating and a large number of new coatings show diversification and series The trend of the column, so that the new brands of hard alloy materials emerge in endlessly, greatly improve the cutting performance of hard alloy tool.