Cutting tool series brand

Based on the classical CF10F, the wettability Angle of grain and liquid phase is strengthened by trace elements to give consideration to toughness and wear resistance. So that our cutting tools in stainless steel, aluminum magnesium alloy and other materials on the processing performance, has been perfect.

| series | brand | Cobalt content(%) | density(g/cm3) | hardness | Bending strength(Mpa) | Scope of application | ||||||||||||||||||||||||||||||||||||||||

| Scope of application | CF03F | 4 | 15.10 | 94.5 | ≥2200 | High hardness grade suitable for milling, reaming and diamond coating. Used for processing aluminum alloy, graphite, composite materials, etc. | ||||||||||||||||||||||||||||||||||||||||

| CF09U | 9 | 14.55 | 93.5 | ≥4000 | Superfine grain alloy, sharp edge, extremely wear-resistant, not easy to deformation. Suitable for milling Knife, reamer. Can be used for high-speed cutting, processing of ultra-high hardness materials (HRC > 60) | |||||||||||||||||||||||||||||||||||||||||

| CF12F | 12 | 14.12 | 92.5 | ≥4300 | Superfine grain alloy, compatible with good hardness and toughness. Suitable for making end milling cutter And reamer for finishing and machining of alloy steels, aluminium alloys and titanium alloys. | |||||||||||||||||||||||||||||||||||||||||

| CF10F | 10 | 14.60 | 92.3 | ≥3800 | Subfine grain alloy, toughness and wear resistance. Suitable for making drill and milling A knife. Can be used for ordinary alloy steel, gray cast iron, stainless steel, heat-resistant alloy processing. | |||||||||||||||||||||||||||||||||||||||||

| VG12F | 12 | 14.13 | 91.3 | ≥3900 | Subfine grain alloy with very high edge collapse resistance. Fit for production Milling cutter, specially for high speed milling of 316L stainless steel. | |||||||||||||||||||||||||||||||||||||||||

| CF08 | 6 | 15.00 | 92.5 | ≥3700 | Corrosion resistant grade, can prevent resin, glue and other chemical effects. Simultaneous resistance to reinforcement Good performance, can be suitable for all kinds of fiber board and particleboard processing. | |||||||||||||||||||||||||||||||||||||||||

| CF10 | 6 | 15.00 | 92.0 | ≥3100 | ||||||||||||||||||||||||||||||||||||||||||

| CF20 | 7 | 14.75 | 91.0 | ≥3200 | Corrosion resistance, collapse resistance, good general performance. Can be suitable for all kinds of hardwood, cork and particle board processing. | |||||||||||||||||||||||||||||||||||||||||

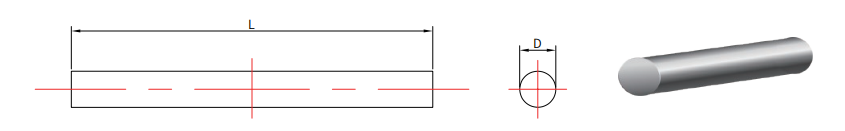

| blank | Fine grindingH6 | length | tolerance | blank | Fine grindingH6 | length | tolerance | |||||||||||||||||||||||||||||||||||||||

| Outside diametermm | tolerance | blankmm | tolerance | |||||||||||||||||||||||||||||||||||||||||||

| φ2.2 | 0-0.3 | φ2.0 | 330 | 0-0.4 | φ17.2 | 0-0.4 | φ17.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ3.2 | 0-0.3 | φ3.0 | 330 | 0-0.4 | φ18.2 | 0-0.4 | φ18.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ4.2 | 0-0.3 | φ4.0 | 330 | 0-0.4 | φ19.2 | 0-0.4 | φ19.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ5.2 | 0-0.3 | φ5.0 | 330 | 0-0.4 | φ20.2 | 0-0.5 | φ20.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ6.2 | 0-0.3 | φ6.0 | 330 | 0-0.4 | φ21.2 | 0-0.5 | φ21.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ7.2 | 0-0.3 | φ7.0 | 330 | 0-0.4 | φ22.2 | 0-0.5 | φ22.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ8.2 | 0-0.3 | φ8.0 | 330 | 0-0.4 | φ23.2 | 0-0.5 | φ23.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ9.2 | 0-0.3 | φ9.0 | 330 | 0-0.4 | φ24.2 | 0-0.6 | φ24.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ10.2 | 0-0.3 | φ10.0 | 330 | 0-0.4 | φ25.2 | 0-0.6 | φ25.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ11.2 | 0-0.3 | φ11.0 | 330 | 0-0.4 | φ26.2 | 0-0.6 | φ26.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ12.2 | 0-0.3 | φ12.0 | 330 | 0-0.4 | φ27.2 | 0-0.6 | φ27.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ13.2 | 0-0.3 | φ13.0 | 330 | 0-0.4 | φ28.2 | 0-0.6 | φ28.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ14.2 | 0-0.3 | φ14.0 | 330 | 0-0.4 | φ29.2 | 0-0.6 | φ29.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ15.2 | 0-0.3 | φ15.0 | 330 | 0-0.4 | φ30.2 | 0-0.6 | φ30.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||

| φ16.2 | 0-0.3 | φ16.0 | 330 | 0-0.4 | φ32.2 | 0-0.6 | φ32.0 | 330 | 0-0.4 | |||||||||||||||||||||||||||||||||||||