Powder metallurgy series brand

For copper powder, iron powder, tungsten carbide, ferrite, zirconia, alumina and other powder products often appear cracking and wear-resistant problems, we consider the diversity and complexity of product structure design a variety of special brands, for different purposes, from the material characteristics, correct material selection.

| series | brand | Cobalt content(%) | density(g/cm3) | hardness | Bending strength(Mpa) | Scope of application | ||||||||||||||||||||||||||||||||||||||||

| Powder metallurgy series | CF06F | 6 | 14.90 | 93.3 | ≥3200 | Superfine grain, high wear resistance and excellent strength. Suitable for soft magnetic materials A high pressure die with a simple equal cavity used as a negative die. | ||||||||||||||||||||||||||||||||||||||||

| CF10F | 10 | 14.60 | 92.3 | ≥3800 | Superfine grain, high wear resistance. Suitable for soft magnetic materials High pressure die with simple cavity, used as Yin die and core rod. | |||||||||||||||||||||||||||||||||||||||||

| CF20 | 7 | 14.75 | 91.0 | ≥3200 | Suitable for iron base, copper base powder metallurgy mold, Used as Yin mold, shaping mold, core rod. | |||||||||||||||||||||||||||||||||||||||||

| CF40 | 10 | 14.62 | 89.5 | ≥3200 | Suitable for iron base, copper base and hard alloy powder metallurgy die, Used as a Yin mold, core rod. | |||||||||||||||||||||||||||||||||||||||||

| VG05 | 12 | 14.32 | 89.0 | ≥3300 | With high strength and wear resistance, suitable for complex shape and pressing Large force of iron powder, copper powder, hard alloy forming die, punch. | |||||||||||||||||||||||||||||||||||||||||

| VG30F | 20 | 13.80 | 88.0 | ≥3400 | Strengthen the liquid phase and adopt the ultrafine grain, the fatigue resistance is strong. Suitable for iron base, Copper base powder metallurgy die, used for special-shaped, curved punch production. | |||||||||||||||||||||||||||||||||||||||||

| VG15 | 14 | 14.15 | 87.5 | ≥3500 | Good toughness, impact resistance, good point processing, Suitable for high load work and complex cavity mold. | |||||||||||||||||||||||||||||||||||||||||

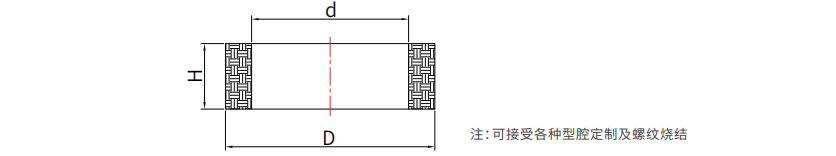

| Outside diameter basic dimension(mm) | Height base dimension(mm) | |||||||||||||||||||||||||||||||||||||||||||||

| ≤30 | 31~64 | 65~109 | 109~159 | 160~240 | ||||||||||||||||||||||||||||||||||||||||||

| Outside diameter (height) tolerance(mm) | ||||||||||||||||||||||||||||||||||||||||||||||

| ≤25 | +1.0 | +1.1 | +1.2 | +1.3 | +1.4 | |||||||||||||||||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||||||||||||||||||||||||||

| 26~39 | +1.4 | +1.5 | +1.6 | +1.7 | +1.8 | |||||||||||||||||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||||||||||||||||||||||||||

| 40~69 | +1.8 | +1.9 | +2.0 | +2.1 | +2.2 | |||||||||||||||||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||||||||||||||||||||||||||

| 70~109 | +2.2 | +2.3 | +2.4 | +2.5 | +2.8 | |||||||||||||||||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||||||||||||||||||||||||||

| 110~159 | +2.8 | +3.0 | +3.2 | +3.2 | +3.5 | |||||||||||||||||||||||||||||||||||||||||

| 0 | 0 | 0 | 0 | 0 | ||||||||||||||||||||||||||||||||||||||||||

| >160 | 2.00% 0 | 2.20% 0 | ||||||||||||||||||||||||||||||||||||||||||||

| Internal diameter basic dimension(mm) | 15 | 16~29 | 30~44 | 45~60 | 60~85 | |||||||||||||||||||||||||||||||||||||||||

| Inside diameter tolerance(mm) | 0 -1.0 | 0 -1.2 | 0 -1.5 | 0 -2.0 | 0 -3.00% | |||||||||||||||||||||||||||||||||||||||||

Note: Other brands and models are available according to user requirements.