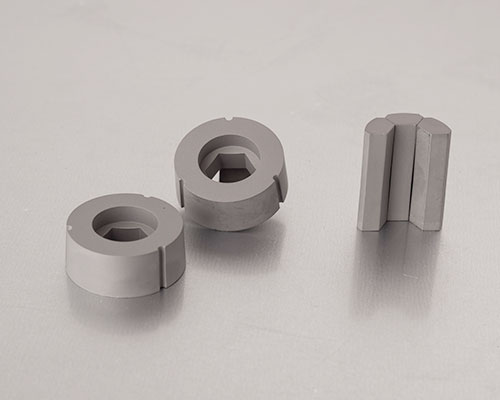

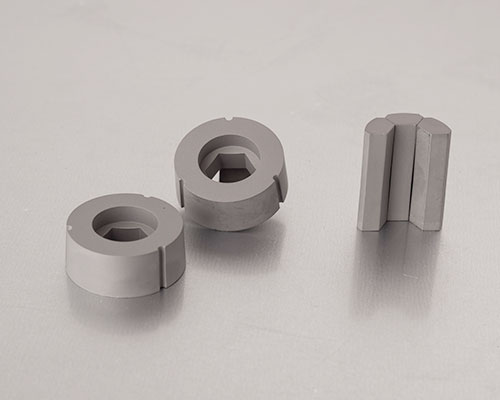

Application of cold heading, hot heading, cold forging and roll

Due to the special working conditions in cold heading and cold rolling fields, the strength of the alloy is higher. We use special grain structure and additives to optimize the strength of the alloy.

Related fields include hardware standard parts, steel balls (beads), auto parts and new materials, such as special silk. In the application of automobile screw die, it can withstand the high strength impact of two station forming. Steel ball, steel ball cold we also designed the formula to make it in mechanical fatigue resistance has been a good strengthening. In addition, the tool life is improved significantly in the tooth profile machining of automobile axle, and the machining surface is smooth and flat. For the rolling series of special new materials such as titanium wire, the roller life is long and stable, which benefits from the perfect combination of special material formula and high precision machining technology.